Introduction

Helium is a critical component of cutting edge research. In its liquid form, which boils at 4 Kelvin (or negative 452 Fahrenheit), helium is used to ensure superconductivity for high end scientific instrumentation in chemistry, biology, and medicine including magnetic resonance imagers (MRIs) and nuclear magnetic resonance spectrometers (NMRs), as well as for state of the art solid state research in physics and materials science. Helium is entirely nonrenewable, produced as a byproduct of certain mining operations, and once it is released it quickly escapes the Earth’s atmosphere. [1]

The cost of research-grade helium has increased up to 400% from 2010 to 2013 in some regions [2] since the federal government has started the process of selling off the Federal Helium Reserve. To help minimize the impact on its researchers, the Dietrich School of Arts & Sciences at the University of Pittsburgh in partnership with the NSF has invested in the creation of a helium recovery program and associated cost recovery center. Pitt Cryogenics is able to provide the University community with research-grade recycled helium at rates greatly reduced from the virgin helium prices provided by outside vendors. Construction of the facility was completed in January of 2015, and the first recovered helium was supplied to the Department of Physics in March.

Helium Timeline

| 1868 | Solar helium discovered by J Norman Lockyer |

| 1895 | Terrestrial helium discovered by Sir William Ramsey |

| 1905 | Liquid helium produced by Kamerling Onnes |

| 1917 | Federal Helium Program created |

| 1918 | Three experimental helium plants constructed in Texas |

| 1921 | First full scale helium production plant created in Fort Worth, TX |

| 1925 | Federal Helium Program moved to Bureau of Mines |

| 1927 | First private helium facility built by Kentucky Oxygen-Hyrogen Co. in Dexter, KS |

| 1927-1929 | Depletion of field near Fort Worth forces shutdown. New plant built in Ammarillo, TX |

| 1937 | Amendment to Helium Act authorizes commercial sale of helium |

| 1948 | Helium Arc Welding developed |

| 1943-1944 | Plants built at Exell, TX, Olis and Cunningham, KS, and Shiprock, NM |

| 1945 | First shipment from Exell to Amarillo for underground storage |

| 1949 | Bureau of Mines develops Grade A helium (99.995% pure) |

| 1960 | Helium Act amended to provide for long term storage |

| 1961 | Kerr-McGee Oil Industries signs four contracts for six government purchased of crude helium for conservation |

| 1962 | First helium delivery under conservation program |

| 1973 | Government ends helium stockpiling and switches to a repleneshment mode of storage in he Bush Dome Reservoir |

| 1996 | Helium Privatization Act passes - Exell plant ceases helium, BLM ordered to sell off helium |

| 2006-2007 | Worldwide helium shortage |

| 2013 | Helium Stewardship Act passed |

| 2015 | Pitt Cryogenics begins operation |

Helium: Sources and Uses

Helium is thought to be the most abundant element in the universe [3], as it the product of the fusion reaction that happens in the heart of stars. On Earth, however helium is exceedingly rare and comprises only 5.2 ppm of Earth’s atmosphere. Most of the helium on Earth comes from radiological sources. As elements like uranium and thorium decay deep underground into thorium and radium, respectively, α-particles consisting of two protons and two neutrons are released and trapped. As these α-particles pick up electrons from their environment they become stable helium atoms.

U238→Th234+α; U235→Th231+α; Th232→Ra228+α

Figure 2: Common Sources of Helium through Radiological Decay. [4]

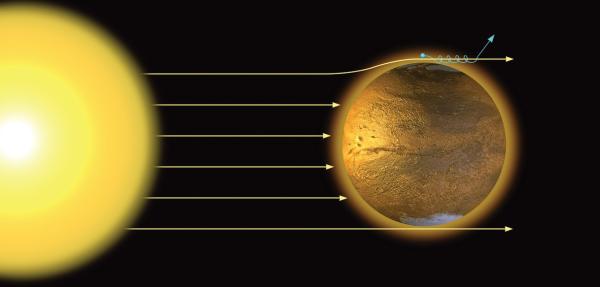

The major sources for terrestrial helium are natural gas deposits that can contain up to 2.7% helium. [5] Because helium is a noble gas with a full electron shell, it is extremely unlikely to react with other chemicals, and once it reaches the surface, rapidly rises to the highest levels of the atmosphere. Over most of the planet, the Earth’s magnetic field lines are able to retain the vast majority of our atmosphere; however over the poles, these field lines trail off due to the solar wind allowing lighter atoms like hydrogen and helium to escape. [6]

Figure 3: Helium Loss From the Polar Wind [6]

This polar wind is the cause of almost all of Earth’s lost helium at a rate of 1600 metric tons per year. [6] [7] For many years and, in many cases still today, radiogenic helium was wasted as a byproduct of the natural gas extraction process. It was only during World War I that the federal government began to recognize the usefulness of the noble gas for potential military applications including dirigible flight. [5] In 1917, Congress authorized the Federal Helium Program and started processing helium in its facility in Texas. The Bureau of Land Management (BLM) under the Department of the Interior extracts and refines helium from the Hugoton shale field in Oklahoma and pipes it into the natural caves of the Bush Dome Reservoir in Amarillo, TX, that are used as the storage facility. As of 2013, 35% and 70% of the world’s helium supply came from the Federal Helium Reserve in specific and the United States in general. [3] [8]

While helium has moved far beyond its original military dirigible use, today it is still used for flight in certain rockets and weather balloons, and for the welding of advanced materials like titanium needed for such crafts using helium arc welding. [9] It is used extensively by deep sea divers to avoid the bends. [9] Most importantly for our purposes it is used in its liquid state at 4K (-452F) to perform cutting edge scientific experiments probing the structure of matter across physics, chemistry, materials science, biology, and medicine.

Technical Overview of Helium Extraction & Refinement

Most of the helium collected and purified in the US comes from Hugoton shale field in Texas, Oklahoma, and Kansas and is sometimes stored in the Bush Dome Reservoir in the Cliffside gas field. [3] [10] Gas is stored in a layer of porous dolomite. [10] Traditionally, wells were operated by the Bureau of Mines as well as several private companies which sold gas to the federal repository. [9] Although all end stage government purification was forced to close by the Helium Privatization Act of 1996, we will focus on the plants previously managed by the BLM as their processes should be indicative of the private facilities now in operation.

Once the incoming gas reaches the initial purification facility it is mixed with helium from the underground storage facility and scrubbed to remove hydrocarbons. [11] The resulting gas containing 20-25% helium is then sent to the CO2 contractor to remove CO2 by contact with an amine glycol solution, and then dried. [12] Although it only makes up 1% of the incoming flow, CO2 has to be removed at this stage as it has a tendency to clog the heat exchangers. [12] Next the gas flows to the Cryo Separator to remove most impurities, resulting in “crude helium” containing 60-80% helium with the balance being traces of N2, H2, and Ne. [11] At this point if the helium is not needed it is returned through the conservation pipeline to the underground storage caves. Today the production of crude helium and its refining are frequently split between different corporations and crude helium is sold as a product between the companies.

If helium is needed for current production it proceeds to the cryo-upgrader which uses several stages of pressurization and depressurization to get to 97% pure helium. [13] At this point more helium may be pulled from underground storage during peak demand. A Deoxo unit is used to remove hydrogen, which will not be removed in the next step, and an additional CO2 unit removes any CO2 introduced from the storage flow. [14] [15] It is here that helium enters the Pressure Swing Adsorption unit, which consists of four molecular sieve exchangers that through pressurization adsorb all incoming gases except hydrogen, helium, and neon. [15] Only one exchanger is operated at a time, while the other three are at various stages of regeneration through depressurization and reverse flow. [15] The process results in 99.997% pure helium, and is the source for helium that passes to the onsite liquefier. [11] Helium gas is also split after the PSA into the Neon removal unit which uses a heat exchanger cooled by 33K helium to condense the remaining neon, resulting in 99.999% pure helium gas. [11]

Government Interaction in the Helium Market

The helium market is a complex one. It is a niche market of a derived product with high barriers to entry. [16] As of 2010 there were only ten refining facilities owned by eight companies in the entire United States, and only six of these, which are owned by four companies, can process the helium stored in the Bush Dome reservoir due to their exclusive access to the Federal Helium Pipeline. [16] Helium production depends almost entirely on the demand for liquid natural gas, and as such suppliers cannot easily respond to increased helium demand by ramping up production. Additionally there has traditionally been neither an effective market nor a market price for crude helium. [16] All crude helium sales proceeded through private contracts, whose terms were not made public, among a small number of crude producers and refiners. [16] The average amount of time from purification to delivery to the ultimate user for helium is 45 to 60 days, meaning that any shortage has an almost immediate impact on the user. [16] Particularly hard hit by changing prices and shortages are academic users, the length of whose grants can force a PI to decide between purchasing helium for experiments and paying graduate students to run them. [16]

As has been stated previously, the Federal Government’s involvement in the helium market began in 1917 with the creation of the Federal Helium Program. The Helium Act was amended in 1937 to allow for private sales of helium and again in 1960 to allow for long term storage in the Bush Dome Reservoir, including the purchase of helium from private suppliers. [9] By 1973, the Federal Government realized that demand was not as high as had been anticipated and ceased the purchase of helium for storage in the reservoir. [9] By 1996, the Federal Helium Program had amassed a $1.3 billion debt and was targeted by the Gingrich Congress for cost reduction. [17] The Helium Privatization Act required that the BLM cease all refining operations (crude helium production was allowed to continue) and sell down the helium in the Bush Dome Reservoir on a straight line basis from 35 billion cubic feet to 600 million cubic feet by January 1, 2015, at prices “sufficient to repay the federal government in full for its initial outlays for the helium, plus interest.” [16] These sales would continue until the lower gas limit was reached or the debt was repaid. [18] It was thought that since the price set by the BLM for crude helium was significantly higher than that of private suppliers, refiners would only purchase helium from the reserve as a last resort, and hence the BLM price would have little effect on consumers. Instead, the private crude supplier price rapidly rose to as much as 10% above the BLM level, causing refiners to purchase from the BLM more frequently than expected. [16] Additionally, as could have been anticipated with a large price increase in its stock material, the price of Grade A helium also spiked, more than tripling between 1999 and 2008. [16] The other major change that occurred to the market was in the consumption patterns of helium. While in 1995 the United States accounted for over 70% of the world demand for helium, due primarily to the shift of semiconductor and optical fiber production facilities overseas, that number has fallen below 50%, resulting in a large volume of helium exported from the country. [16]

By 2013, the BLM had recouped the $1.3 billion of debt it had incurred, even though it was now selling below market cost and still had 13.7 billion cubic feet of gas in the ground, and was required to cease sales of helium according to the 1996 Act, leading to a tremendous disruption in the market. [17] In response, Congress passed the Helium Stewardship Act of 2013 which mandated that: first, the BLM would continue to sell helium until around 2021; and second, they would hold auctions for a portion the crude helium to obtain a market price and increase competition. [18] Previously crude helium sales have been split between refiners and nonrefiners, and nonrefiners would pay a “tolling deal” to the refining companies to process their helium. [18] These auctions would start at 10% of the helium sold from the reservoir and increase in later years. [18] The first auction was held in 2014, and although it did produce a market price, it did not increase competition as Congress had hoped. [18] Only two companies purchased helium and drove the price to over 52% more than the fixed price for the remaining 90% of crude helium sold by the BLM, effectively paying a premium to block entry to non-refining helium companies. [18]

References

[1] S. Connor, "Why the World is Running Out of Helium," The Independent, 23 August 2010.

[2] M. Peplow, "Helium Reserves Under Pressure," Chemistry World, 30 May 2013.

[3] B. Magill, "Popular Mechanics: Why Is There a Helium Shortage," 25 June 2012. [Online]. [Accessed 13 November 2015].

[4] J. Lowenstern, W. Evans, D. Bergfeld, and A. Hunt, "Prodigious degassing of a billion years of accumulated radiogenic helium at Yellowstone," Nature, vol. 506, no. 20 February 2014, pp. 335-358, 2014.

[5] "BLM: Helium Program - About Helium," 24 June 2015. [Online]. [Accessed 06 November 2015].

[6] D. Catling and K. Zahnle, "The Planetary Air Leak," Scientific American, vol. May, pp. 36-43, May 2009.

[7] C. McDonald, "BBC News: Who, What, Why: Is the Earth getting lighter?," 31 January 2012. [Online]. [Accessed 13 November 2015].

[8] B. Magill, "Popular Mechanics: As Shortage Worsens, We Visit the Federal Helium Reserve," 12 November 2012 . [Online]. [Accessed 13 November 2015].

[9] "Helium Production and Use," 2001. [Online]. [Accessed 15 Nov 2015].

[10] "Helium Activities," 2001. [Online]. Available: [Accessed 15 Nov 2015].

[11] "Helium Production Process - Exell Helium Plant," 2001. [Online]. [Accessed 15 November 2015].

[12] "Natural gas Treatment Process - Exell Helium Plant," 2001. [Online]. [Accessed 15 November 2015].

[13] "Helium Production Process - Amarillo Helium Plant," 2001. [Online]. [Accessed 15 November 2015].

[14] "Crude Helium Separation Process - Exell Helium Plant," 2001. [Online]. [Accessed 15 November 2015].

[15] "Purification Process - Excell Helium Plant," 2001. [Online]. [Accessed 15 Novemeber 2015].

[16] National Materials Advisory Board, Committee on Understanding the Impact of Selling the Helium Reserve, Board on Physics and Astronomy, Division on Engineering and Physical Sciences, National Research Council, Selling the Nation's Helium Reserve, The National Academies Press, 2010.

[17] A. Cho, "U.S. Senate Committee Holds Hearing on Helium Bill," Science, 7 May 2013.

[18] A. Cho, "New U.S. Rules on Helium Sales Said to Stifle Competition," Science, 8 July 2015.