In the three decades that Tom Gasmire has been building items for Pitt scientists, he has contributed to a lot of groundbreaking research by creating equipment that doesn’t exist. It’s one of the things he likes best about working for a university: the opportunity to build a piece of apparatus that assists a professor or graduate student while also stretching the bounds of Gasmire’s own creativity.

So when doctoral student Eden McQueen told him she needed a brothel for fruit flies, he was more than up to the task.

McQueen studies the genital structure of fruit flies as part of the evolutionary development lab headed by Mark Rebeiz, an assistant professor in the Department of Biological Sciences. According to Rebeiz, reproductive systems are some of the most rapidly evolving structures in animals. McQueen was interested in learning how the differences in those structures affect the fruit flies’ mating behavior.

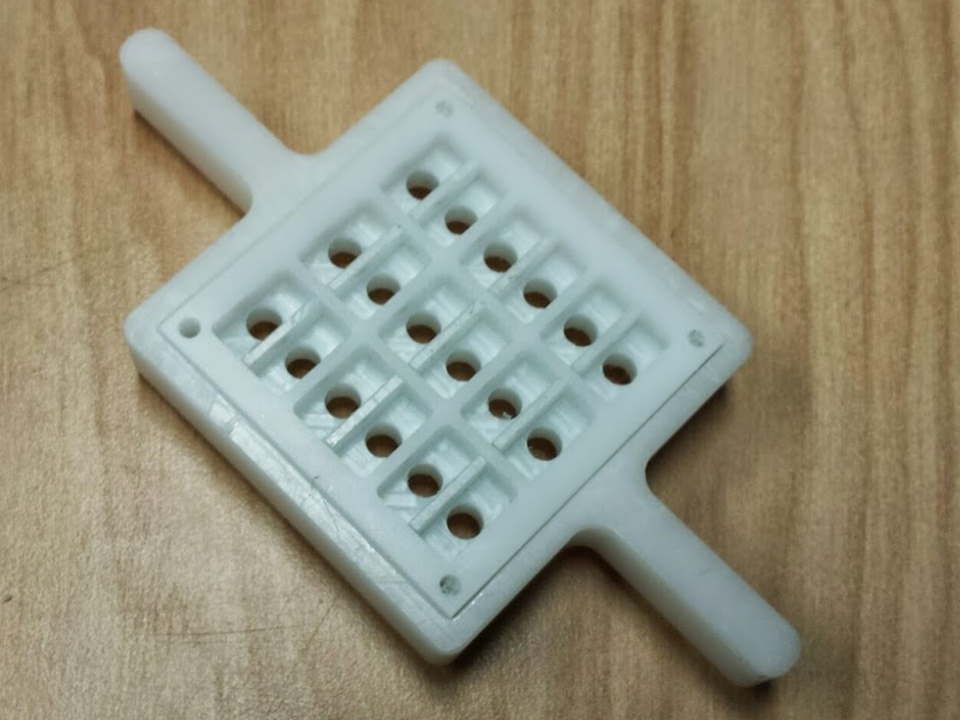

To measure that, she told Gasmire she needed breeding chambers that would separate male and female flies until she had them under a microscope and could begin filming them. Then she wanted to retract the walls that separated them so she could capture the mating process from start to finish.

“I always try to keep things as simple as possible,” says Gasmire, who supervises the machine shop.

At first, he built a device that included nine tiny square chambers, which combined had to fit within 1 ½ square inches, with walls that retracted at the push of a button. But when McQueen used it, she ran into an unexpected problem: once she retracted the walls, the female fruit flies quickly retreated to the corners to fend off the advances of the males.

Gasmire then reduced the number of chambers and made them round, so the females would have nowhere to hide. And McQueen was able to view the results with the help of the Microscopy and Imaging Suite, where she filmed the mating inside the chambers with the help of Leica M165 stereoscope, creating small movies for scientific presentations.

“It was a really inventive design that Tom came up with,” says Rebeiz. “I was impressed with how helpful they were in making this project work, and certainly Eden’s mentioned it to a lot of people.”

Prior to McQueen’s project, Rebeiz had not known how about the existence of the machine shop, but he plans on making use of it in the future.

“There’s always a need to come up with a unique tool,” he says. “Having the ability to come up with custom equipment at just the cost of the materials is a huge resource for us, and we definitely will use it again.”