Introduction

Helium: Sources and Uses

Technical Overview of Helium Extraction & Refinement

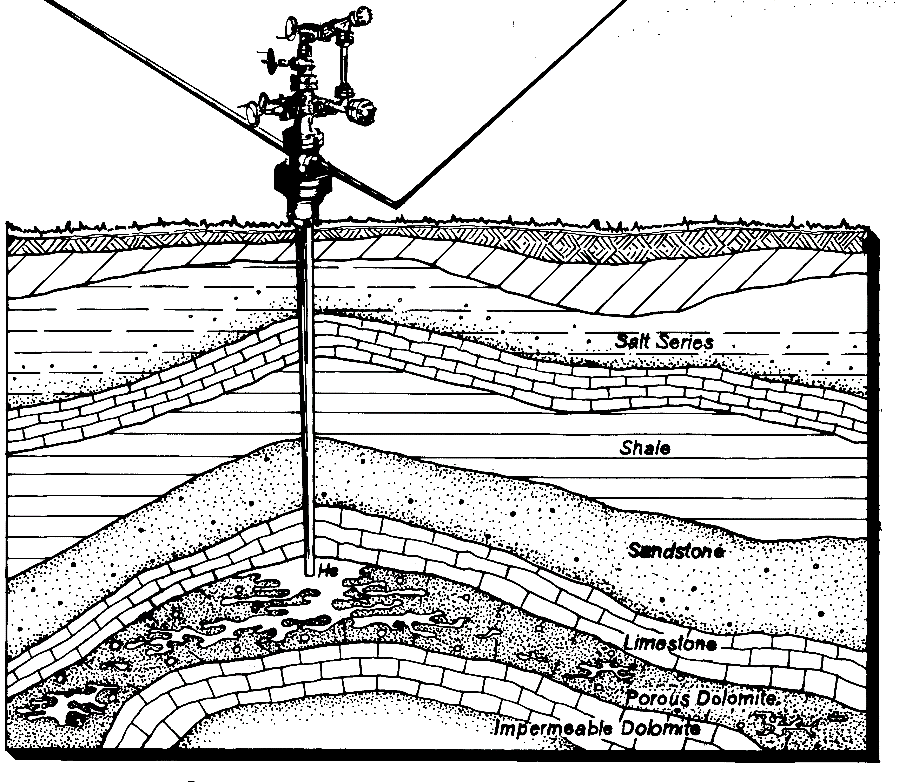

Figure 4: Geological Layers in the Cliffside Gas Field [10]

Most of the helium collected and purified in the US comes from Hugoton shale field in Texas, Oklahoma, and Kansas and is sometimes stored in the Bush Dome Reservoir in the Cliffside gas field. [3] [10] Gas is stored in a layer of porous dolomite. [10] Traditionally, wells were operated by the Bureau of Mines as well as several private companies which sold gas to the federal repository. [9] Although all end stage government purification was forced to close by the Helium Privatization Act of 1996, we will focus on the plants previously managed by the BLM as their processes should be indicative of the private facilities now in operation.

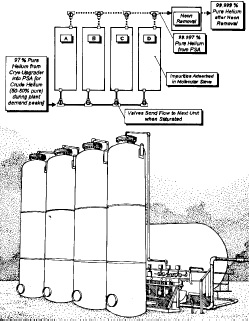

Figure 5: Schematic Diagram of the Helium Production Process at the Exell Plant [11]

Once the incoming gas reaches the initial purification facility it is mixed with helium from the underground storage facility and scrubbed to remove hydrocarbons. [11] The resulting gas containing 20-25% helium is then sent to the CO2 contractor to remove CO2 by contact with an amine glycol solution, and then dried. [12] Although it only makes up 1% of the incoming flow, CO2 has to be removed at this stage as it has a tendency to clog the heat exchangers. [12] Next the gas flows to the Cryo Separator to remove most impurities, resulting in “crude helium” containing 60-80% helium with the balance being traces of N2, H2, and Ne. [11] At this point if the helium is not needed it is returned through the conservation pipeline to the underground storage caves. Today the production of crude helium and its refining are frequently split between different corporations and crude helium is sold as a product between the companies.

Figure 6: Pressure Swing Adsorption Unit at the Exell Plant. [15]

If helium is needed for current production it proceeds to the cryo-upgrader which uses several stages of pressurization and depressurization to get to 97% pure helium. [13] At this point more helium may be pulled from underground storage during peak demand. A Deoxo unit is used to remove hydrogen, which will not be removed in the next step, and an additional CO2 unit removes any CO2 introduced from the storage flow. [14] [15] It is here that helium enters the Pressure Swing Adsorption unit, which consists of four molecular sieve exchangers that through pressurization adsorb all incoming gases except hydrogen, helium, and neon. [15] Only one exchanger is operated at a time, while the other three are at various stages of regeneration through depressurization and reverse flow. [15] The process results in 99.997% pure helium, and is the source for helium that passes to the onsite liquefier. [11] Helium gas is also split after the PSA into the Neon removal unit which uses a heat exchanger cooled by 33K helium to condense the remaining neon, resulting in 99.999% pure helium gas. [11]